|

Manual for

SPACEPLATES GREENHOUSE

Introduction:

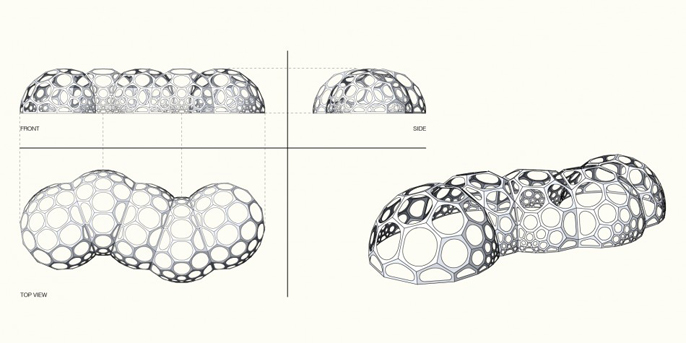

The SPACEPLATES GREENHOUSE is a greenhouse version of new building system developed by N55 in collaboration with Anne Romme. The SPACEPLATES building system is a result of an ongoing research project into the use of "pure plate structures" The SPACEPLATES building system is a light weight, minimal material, low cost system that enables persons to build any scale of structures shaped as approximated doubly curved surfaces in a statically well defined way customized for living purposes, production purposes etc.

Construction:

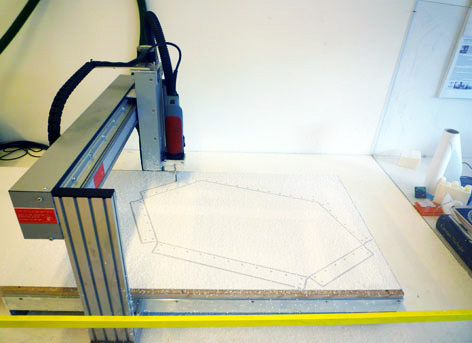

While the design is based on digital modeling and the production of the parts on CNC-technology, the assembly method is so simple that it allows anyone to construct their own greenhouse without a complicated instruction manual and with no other tools than a wrench or a drill to tighten nuts and bolts.

Further development of the project will include a "design your own greenhouse" digital process, where also the size, overall form and geometrical pattern is adjustable according to individual desires and needs. In this way the SPACEPLATES system becomes an example of art/ architecture/ design, where the developer of the system doesn't use it to express him or herself etc, but simply delivers a basic set of intelligent rules for the fabrication of a building, that secures a high standard of construction and allows persons to shape their own building the way they think is best.

Background:

The late Danish engineer Ture Wester identified an unexploited potential in using "pure plate" structures for constructing approximated doubly curved surfaces in architecture. We have taken up that challenge. By means of digital design and fabrication, and based on Wester's significant work on the dualistic geometric and structural relationship between lattice and plate structures, we have developed a modular building system named SPACEPLATES. Similar to the well-known term space frame, SPACEPLATES is also a rigid lightweight structure able to carry loads simultaneously through compression and tension forces. The difference is, as the name suggests, that the SPACEPLATES Building System is based on plates as structural members rather than a frame of struts and nodes. Based on pure plate structure, the system uses no other structural members than thin plates, bent at all edges to achieve a simple mechanical assembly method. While the design and the production requires digital technology, the SPACEPLATES structure itself can be assembled using only hand tools.

Structure and geometry:

Unlike the classical load-bearing greenhouse structures based on compression (a stiff structure of posts and beams supporting the transparent cladding material) the SPACEPLATES GREENHOUSE takes advantage of its light material and a structural method called pure plate structures, which combines compression and tension forces working within the cladding material itself, needing no primary supportive structure. This also separates the SPACEPLATE method from spaceframe constructions like the geodesic dome. lattice structures forming structures like that are very well researched and understood. Plate based structures are not. Especially not when it comes to more freely formed, complex, tesselated shapes that are not plain domes.

Pure plate structure is an elegant way of creating doubly curved forms. Unlike the triangulated lattice structures used in much contemporary architecture, in pure plate structure the structural system and the cladding is one and the same thing.The geometrical and structural characteristics allow for extremely economical and simple building systems at any scale from small units to larger spans.

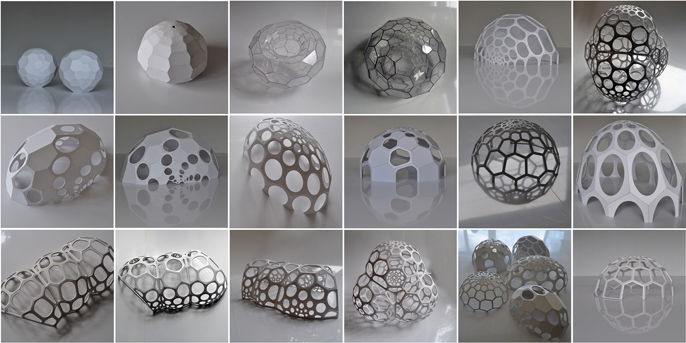

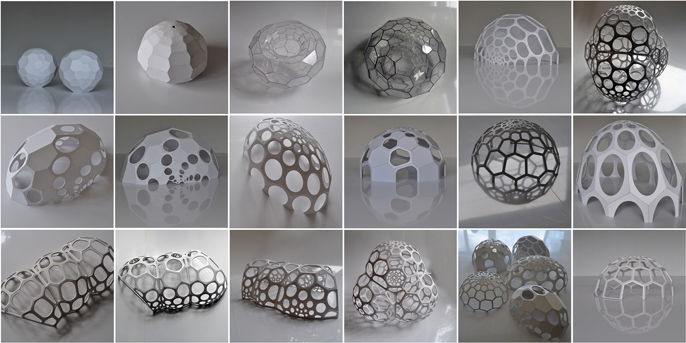

Unlike Buckminster Fuller's well-known and well-tested domes where the number of different parts are kept at a minimum, the SPACEPLATES building system takes advantage of contemporary technology to mimic more complex naturally occurring geometries. Because of an organic growth principle, they often contain a gradience, and thus many geometrically similar but differently sized parts.

As an example the SPACEPLATES GREENHOUSE prototype is based on the sea urchin geometry, where hexagons of increasing size form a spherical form.

There is an intricate dependency between the geometry and the structural capacities of SPACEPLATES. Hexagonal tessellation results in Y-shaped vertices at any given joint, which allows for an ideal distribution of forces within the surface of each plate. This has been documented well in current research, see structural engineer Ture Westers work on this (for example "Structural order in space") or structural engineer Anne Bagger's PhD dissertation.

History of the SPACEPLATES GREENHOUSE:

After two years of research in "pure plate structures", N55 and Anne Romme decided to build the first prototype:

The SPACEPLATES GREENHOUSE prototype was placed in public space on Krøyers Plads in the center of Copenhagen. It is an example of how food can be produced within the city. A parking space would be sufficient land to grow significant amounts of food. Because it is light-weight, easily constructed and moved, and because the overall size and form can be adjusted to any small available plot of land, the SPACEPLATE GREENHOUSE has the flexibility to be placed anywhere where people have the need and desire to grow food for a season or more.

The land which is now occupied by one-family houses in the suburbia surrounding all Western cities was once farming land for the production of food for the city. As the building of the suburbs has pushed farming land further and further away from the city, our food production gradually has become increasingly industrialized. Today the connection between the land of the suburbs and the dinner table of the city has almost disappeared. The SPACEPLATES GREENHOUSE makes local food production possible for anyone who has the desire to grow and eat their own food.

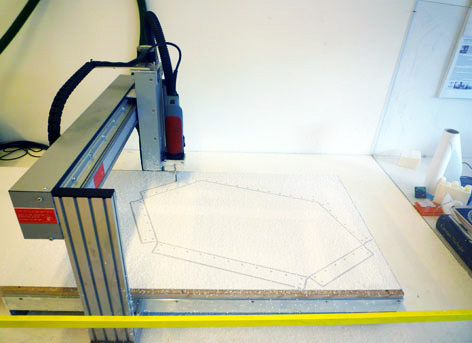

CNC router used for the prototype

Testing the prototype structure by applying a swing to the top. ( no sign of deformation)

The SPACEPLATES GREENHOUSE prototype was moved to Prags Have, a community urban garden situated in Copenhagen, in the spring of 2012. Until a larger structure has been build on this site, hopefully the summer of 2013, the prototype will serve as Prags Have's greenhouse. Straps used for transportation has not been removed, but tomatoes and other plants have settled in…

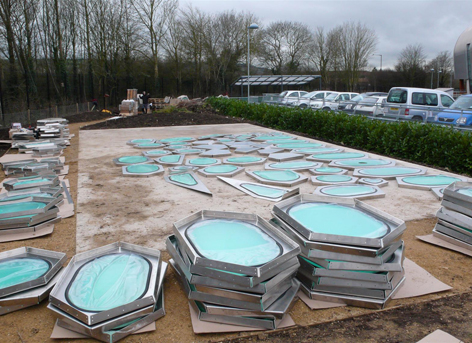

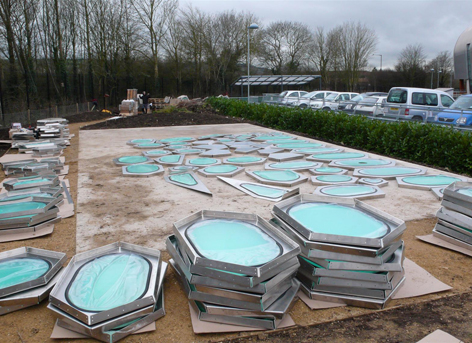

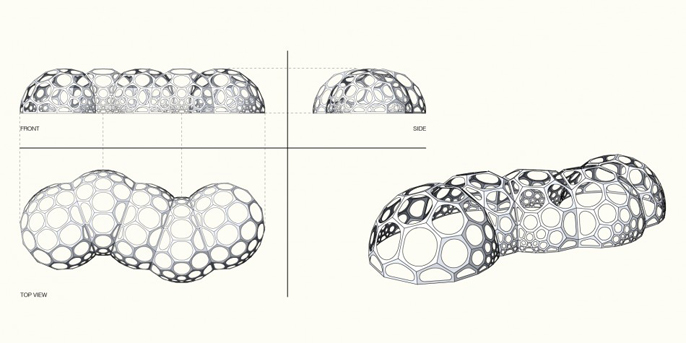

The SPACEPLATES GREENHOUSE in Bristol was completed in 2012. Wedged in on a minimal site surrounded by large parking lots, the 72 m2 structure functions as a class room and growing space for horticulture students and their teachers at the South Bristol Skills Academy. The greenhouse enables them to study and grow plants all year round, and will be used for seeding and growing plants for the outdoor gardens adjacent to the site. The building consists of five distorted half-spheres intersecting each other to form one long space. The building is placed on a concrete foundation. The plates are made from aluminum and acrylic windows fitted using a rubber profile.

> >

> >

Bristol, UK

Testing a section of the structure in Copenhagen.

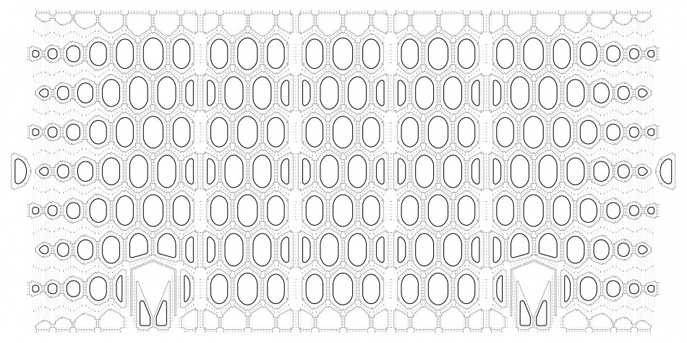

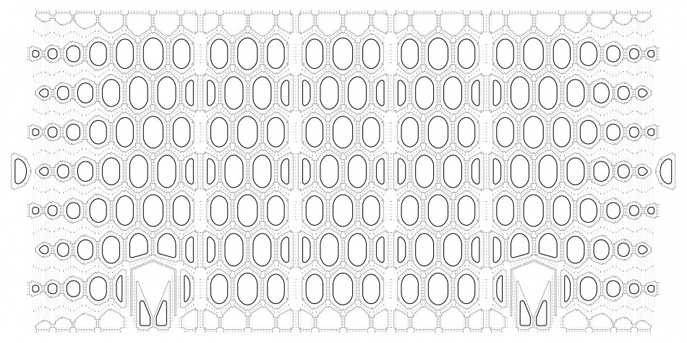

Master drawing of all of the parts of the SPACEPLATES GREENHOUSE in Bristol

A paper written for the International Conference Structures and Architecture 2013 will be published here when we are allowed to ( after the official publication has been launched)

17.11.2012:

At the moment we are working on a proposal for a large structure fro Prags Communal Garden in Copenhagen. We are researching different ways of building using different geometries. We are also introducing solutions for negative curvature to the system. We are developing an insulated version of the system to be able to build houses. Prototyping will begin spring 2013.

Work in progress: Proposal for Prags Communal Garden.

Technical specifications:

SPACEPLATES GREENHOUSE PROTOTYPE:

PARTS

239 hexagonal polycarbonate plates, 3mm thickness, UV-protected.

Approximated 138 m Neoprene rubber sealing

Bolts, nuts and washers

SPACEPLATES GREENHOUSE Bristol version:

PARTS

228 4 mm aluminum plates

174 windows made from acrylic plates

6964 knots and bolts

429 m rubber profile.

Sealant

concrete foundation

SPACEPLATES GREENHOUSE SITUATIONS:

> >

By N55, Ion Sørvin in collaboration with Anne Romme

Structural engineer on the Bristol SPACEPLATES GREENHOUSE: Anne Bagger

Current SPACEPLATES research team: Anne Romme, Ion Sørvin, Anne Bagger

Special thanks to Johann Rooijackers for his contributions.

Special thanks to Till Wolfer for managing the building site in Bristol.

Special thanks to Erling Sørvin for foundation design advice

Thanks to:

Kristin Saunders, Bill Mckenna, Nicolai Fontain, Jacob Coln, Lene Slot Hansen, Anne Bagger, Sam Kronick, Lena G Franck, Thom Gavin and to Jamie Woodley Photography /Ginkgo project for the first six photos in this manual.

Back to manuals

Back to HOME

|

>

> >

>

>

>