Manual for

N55 SPACEFRAME

N55 SPACEFRAME, 1999. Music

by Anders Remmer

N55 SPACEFRAME, 1999. Music

by Anders Remmer

Introduction:

The N55 SPACEFRAME is a low-cost, movable lightweight construction

that can easily be transformed. It is dimensioned as a living unit for

3-4 persons and demands practically no maintenance. The construction can

be erected by anybody in a short time.

The N55 SPACEFRAME is configured as a truncated tetrahedron with an indoor

ground floor of approx. 20 m2. According to needs and economy, the size

and configuration may be changed, and extra floors and rooms may be included:

it is easy to add to the construction in stages.

The entire unit is constructed from small lightweight components which

all can be handled without the use of cranes or other heavy machinery.

All components are materially minimised, have a low degree of manufacturing

and are produced by a few simple machines, which anybody can operate.

When stacked, the components take up very little space. The construction

is assembled by hand. It can be erected directly onto the ground, since

a cast foundation is not necessary. The structure can be dismantled and

rebuilt many times over without damaging any of the components. The construction

can be moved either fully assembled, or partly dismantled.

Technical background:

By constructing spaceframes one is able to utilize geometry to achieve

very strong, self-load-bearing structures and at the same time save materials

and work.

The building system in N55 SPACEFRAME is configured as a space lattice

known as the common space lattice, the octet truss, or the octahedron-tetrahedron

complex.

The geometry of this space lattice does not depend on gravity for strength

or integrity, and therefore is suitable for employment in satellites and

space platforms, in big halls etc, but is rarely employed for housing

and other small-scale purposes.

The distribution of tensile and compressive forces, the rigidity and the

ability of the structure to deform locally makes it safe under extreme

conditions like earthquakes or sudden impacts. Because of the geometry,

loads are distributed well throughout the construction.

All the struts in the construction are of equal length, ensuring an economic

production with few different components.

The octet truss is among the structures in which one obtains the greatest

strength using the least materials.

Construction:

The struts used in the building system for the N55 SPACEFRAME are acid

resistant stainless steel, highly durable, prepared for numerous reassemblies

and chemically immune to most conditions. The equal-length struts are

bent in 70° angles for tetrahedra and 110° angles for octahedra.

The struts are assembled by hand using stainless acid resistant bolts

and nuts that are tightened with a screwdriver. Two tetrahedra and one

octahedron make the basic building "brick", with which one can

build walls, foundation and roof.

The structure can be thinned out to use fewer struts. The resulting space

enclosure has walls of 50 cm, inclining at angles of 70° and 110°.

The walls can be filled with insulating material, or be used as cupboards,

to hide electrical installations or for growing plants inside.

On the outside the construction is covered with plates in acid resistant

stainless steel, which need no maintenance.

Inside planes are covered with moisture-absorbing plaster-fibreboard plates.

The floor is made of birch plywood and polycarbonate is used for windows.

The window frame is covered with plates of insulating, light-reflecting

polyethylene foam.

The door is a plate of honeycomb aluminium. Polycarbonate is used for

skylight. If the walls are properly insulated, there should be no need

to heat the room except under extreme conditions. Lighting, sun radiation,

cooking and normal activities will provide sufficient heating. All kinds

of insulating material can be used: Rockwool, sheep wool, paper, polystyrene,

and so on.

During assembly one may

climb in the structure, using a climbing harness for security

During assembly one may

climb in the structure, using a climbing harness for security

.

Assembly:

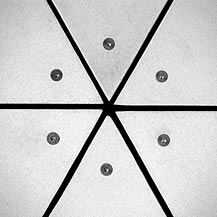

Alternating tetrahedra/octahedra are put together to form girders which

are combined to form the base. The walls are built onto the base one girder

at the time. During assembly, the struts are bolted only loosely together,

and the bolts are finally tightened when all the parts of a layer are

in place.

|

The construction is built

using two kinds of struts: Tetrahedra are assembled using 6 pc 70°

struts. 12 pc 110° struts for octahedra are then attached to

the tetrahedra. |

|

Two tetrahedra, one octahedron:

the "brick" in the construction. This configuration fills

space in all directions. |

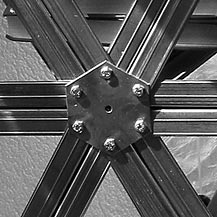

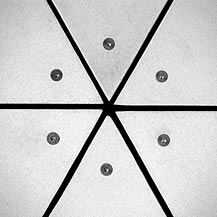

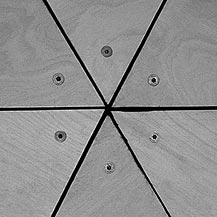

|

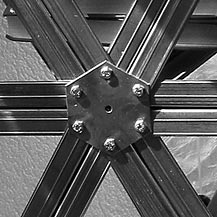

The struts are overlapping

each other in a regular pattern. |

|

Fishplates are bolted onto

all meeting points in order to increase rigidity of the inner and

outer plane (“stressed skin”). |

|

Foundation:

Polyethylene plastic tanks are built into the lowest level in the

construction. The tanks are each filled with approx. 90 liters of

water, together adding about 3 tons to the total weight of the construction.

One can also use earthspears or fill the lower level with sand.

Shields may be attached to prevent moisture and scavengers from

entering from below. |

|

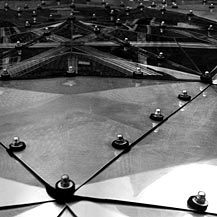

Roof:

The roof is covered with plates of stainless steel and polycarbonate,

mounted with draught strips and rubber. The roof has one central

summit and one in each corner. The height and decline of the plates

is regulated with wedges and long screws.

|

|

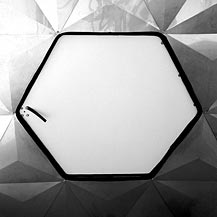

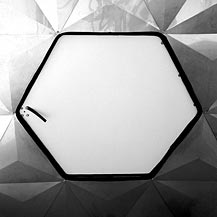

Door:

The entrance is a hexagonal hole which is closed with an aluminium

honeycomb plate. The door is closed by pulling the rubber handle

and turning the key.

|

|

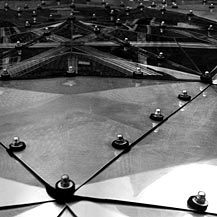

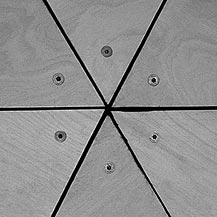

Outside

plating: The construction

is faced using stainless acid resistant steel triangles and squares.

The plates overlap and the tightness is regulated with wedges.

This surface demands no treatment or maintenance.

|

|

Windows:

The construction is slightly dynamic and is influenced by temperatures.

Glass is therefore not suited for windows and polycarbonate is used

instead. A slight deformation of the material will not cause it

to break. The windows are opened and closed by regulating the long

fixture screw at their low corners.

|

|

Window

frames:

The window frames are covered with plates of polyethylene-foam, which

is easy to cut and mount and reflects light.

|

|

Inside

plating:

Plaster-fiberboard plates are used to cover the inner walls. The plates

are treated with varnish and mounted with draught strips.

|

|

Floor:

Birch plywood, varnished, mounted with wedges and draught strips.

|

|

The octahedron-tetrahedron

complex has been discovered and formulated within various contexts:

chemistry, physics, mathematics and other. A construction system (the

"octet truss") which makes use of this geometry was patented

in the 1940´s by R. Buckminster Fuller, USA. The system was

used as a curved space frame for building the Ford Rotunda in Detroit. |

| All parts, except insulating material, can be

stacked and stored to fill a minimum of space, e.g. in an apartment. |

Maintenance:

There is no need for maintenance of the main construction or the outside

plating. The floor and walls may need extra varnish every now and then.

Technical specifications:

Weight: approx. 4.5 tons.

Height/width: approx. 5.5 m.

Component list:

Main construction:

Approx. 3000 pc 110° / 4500 pc 70° struts, 1 mm stainless, acid-resistant

steel AISI 316 L. 144 pc 55° struts for mounting square outside plates.

All struts with 4 pc holes Ø 6 mm. Approx. 8000 pc M6 x 12 mm stainless

set screws and M6 stainless lock nuts. Fishplates 80 mm, hole Ø 6.5

mm.

Outside plating:

540 pc 62.5 cm regular triangles / 36 pc 62.5 x 65 cm squares in 1 mm stainless,

acid-resistant steel AISI 316 L, M6 x 100 stainless set screw, M6 top nut,

24/ 8 mm disc, M6 stainless nut, 6/10 mm draught strip, nylon wedges.

Inside plating:

330 pc 60 cm triangles, 3 squares in 10 mm plaster/fibreboard, acid proof

insex screw M6 x 35 mm, 24/8 mm disc, M6 stainless nut, 6/10 mm draught

strip.

Windows:

60 pc 60 cm triangles in 4 mm polycarbonate, stainless insex screw M6 x

35 mm, 24/8 mm disc, M6 stainless nut, 6/10 mm draught strip, nylon wedges.

Window frame: 35 mm polyethylene-foam.

Floor:

110 pc 60 mm triangles in 10 mm birch plywood, stainless insex screw M6

x 35 mm, 24/8 mm disc, M6 stainless nut, 6/10 mm draught strip, nylon wedges.

Roof:

6 pc 62.5 cm triangles in polycarbonate, 27 pc 62.5 triangles in stainless,

acid-resistant steel AISI 316 L. All plates with 12 holes Ø 7 mm,

M6 x 100 mm stainless set screw, 24/8 mm disc, M6 stainless nut, 6/10 mm

draught strip, flat rubber washer, nylon wedges.

Door:

Hexagonal 6 mm sandwich plate, 120 cm across, 10 mm rubber strip, rubber

handle, lock.

Foundation tanks:

31 pc low density PE tanks with water and disinfectant.

N55

SPACEFRAME situations

Back

to MANUALS

Back to HOME

|

N55 SPACEFRAME, 1999. Music

by Anders Remmer

N55 SPACEFRAME, 1999. Music

by Anders Remmer